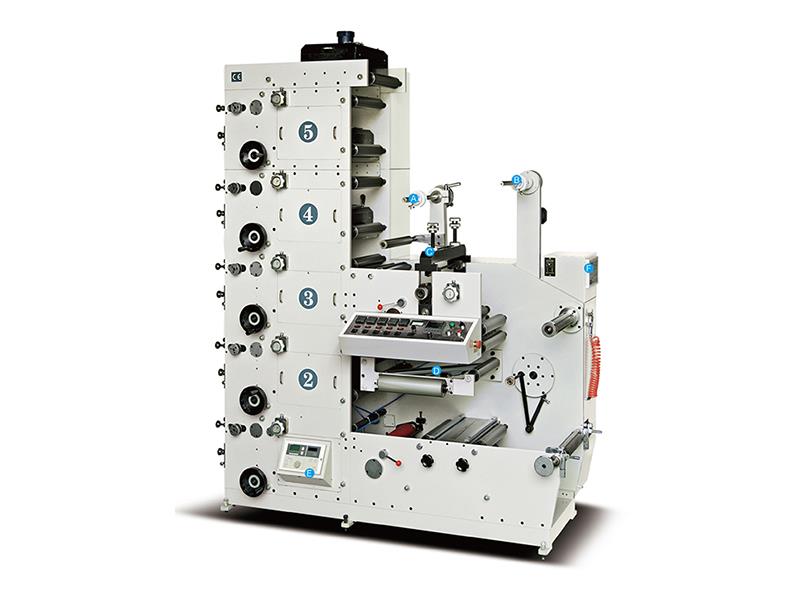

Station for 4-color flexo printing machine:

1.One mounting device

2.One anilox roller for each group

3.Three sets printing rollers

4.Printing both sides at the same time (with turn bar)

With lamination station.

6.One unwinding tension controller

7.One rewinding tension controller

8.One rotary die cutting station comes with air shaft type matrix rewinder

9.With Chinese web guiding

10.Each printing station with both IR.

Technical Parameters

|

Model |

RY320-4B |

|

Printing speed |

60m/min |

|

Printing color |

4colors |

|

Max.Web width |

320mm |

|

Max.Printing width |

310mm |

|

Max.Unwinding diameter |

600mm |

|

Max.Rewinding diameter |

550mm |

|

Printing girth |

175-580mm |

|

Precision of registration |

t0.10mm |

|

Dimensions |

2100*1100*3300(mm) |

|

Machine weight |

About3000kg |

Electrical brand

|

NO. |

ltem |

Brand,Origin country |

|

1 |

Unwinding Tension Contoller |

Mistubishi Japan |

|

2 |

Rewinding Tension Controller |

Mistubishi Japan |

|

3 |

lnverter |

Schneider Germany |

|

4 |

Breaker |

Schneider Germany |

|

5 |

Buttons |

Schneider Germany |

|

6 |

AC contactor |

Schneider Germany |

Characteristics:

1.Adopt the anilox roller to spread ink.

2.Unwinding and rewinding are controlled by magnetism power brake, clutch. (or by automatic tension controller of mitsubishi , made in Japan).

3.Printing unit adopt 360º for registration.

4.Printing unit have one infrared to dry the device group each.

5.The rubber roller can break away from automatically while parking, and running at a low speed, in order to avoid water being black to be dry.

6.The main motor is adopted the import stepless regulation of frequency conversion.

7.Unwinding, printing, varnishing, IR drying, laminating and rewinding can be finished in one process, this kind of printing machine is best for each printing companies to print on adhesive-paper labels and other commercial label.

1. Advanced equipment: Highsee has advanced processing equipment that can meet various complex processing needs, ensuring that each process meets customer requirements and international standards.

2. Exquisite technology: Highsee has an experienced technical team that can provide professional processing solutions and technical support, helping customers save a lot of costs.

3. Quality assurance: Highsee strictly implements the quality management system to ensure product quality. All the machines developed have passed ISO9001 and other international quality management system certifications to ensure that product quality meets international standards.

4. Customer first: Highsee always puts customer needs first and strives to provide satisfactory processing solutions and services.

5. R&D strength: Highsee has a strong R&D team and the ability to continuously launch new products. Highsee has a number of patented technologies and can produce energy-saving, efficient and intelligent slitting machines, cross-cutting machines, packaging machines and other machines.

6. Brand awareness: Highsee enjoys a high reputation in the industry. Customers are more inclined to buy our slitting machines, cross-cutting machines and other equipment with reliable quality and good lifelong after-sales service.

7. Market position: Highsee slitting machines, cross-cutting machines and other equipment cover multiple industries and have established long-term cooperative relationships with many well-known companies, such as APP Paper, Sun Paper, Kailai Paper, etc. Has exported to America, UK, Germany, Saudi Arabia, Brazil, Turkey, Egypt, Tunisia, Indonesia, Vietnam, etc.

8. Production scale: Highsee has been engaged in the slitting machine and cross-cutting machine industry for more than 20 years and has large-scale production capabilities, which can reduce the procurement cost and manufacturing cost of unit products.

These advantages of Highsee constitute our competitiveness in the market, helping customers win in the fierce market competition

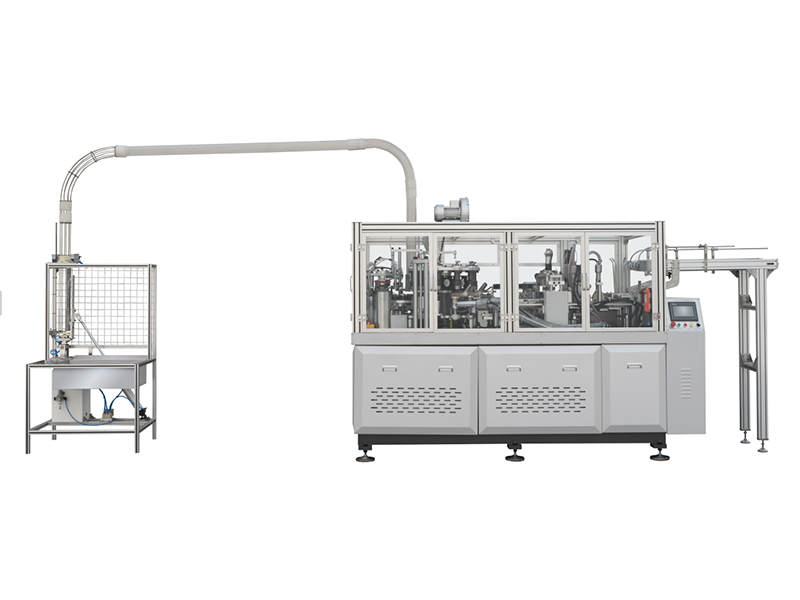

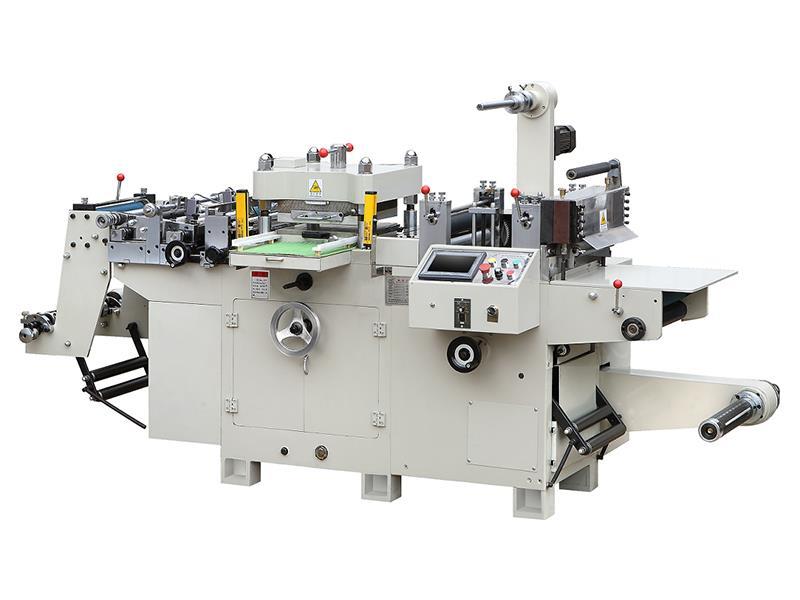

Wenzhou Highsee Packing Machinery Co., Ltd.is the top branch of Gaobao Group,specializing in manufacturing roll to roll slitting and rewinding machine ,roll to sheet cutting machine ,packing machine for A4 paper and all kinds of other film,paper,non-woven,label materials for more than 20 years.We focus on technological innovation and quality control and after-sale service.It's widely recognized by the domestic and oversea market and has gained quite good reputations from old customers.Highsee Machinery consists of technical development department, manufacturing department, domestic and international sales department and after-sales service department.Machine with lSO9001 Quality Management System Certificate and CE Certificate and International Patents. Machinery has exported more than 80 countries: Asia(such as Turkey,Pakistan,Korea, India, Thailand, Vietnam, Indonesia, Malaysia,ect),Europe (France,Russia, Bulgaria, Croatia,Romania, Spain, ltaly,UK,ect), Africa (Algeria,Egypt,Tunisia,Uganda,etc), expecially in North America and South America,almost all paper related factories are using our machinery,such as America,Mexico,Brazil,Canada Argentina,ect.

We hope to establish good and long-term business cooperation with customers from all over the world.